Dholera, one of India’s most ambitious smart city projects, is a testament to the country’s rapid urbanization and technological advancement. Located in the state of Gujarat, the Dholera Special Investment Region (DSIR) aims to be a hub of industrial, residential, and infrastructural excellence. As Dholera advances towards becoming a model for future smart cities, innovative technologies are playing a crucial role in shaping its landscape. Among these technologies, 3D printing stands out as a transformative force in construction, promising to redefine how buildings and infrastructure are designed, constructed, and maintained.

In this blog, we will explore the multifaceted role of 3D printing in the construction of Dholera, examining its benefits, challenges, and future prospects. We’ll delve into how 3D printing is being integrated into the city’s development plans and its potential to revolutionize urban development on a broader scale.

The Emergence of Dholera: A Vision for the Future

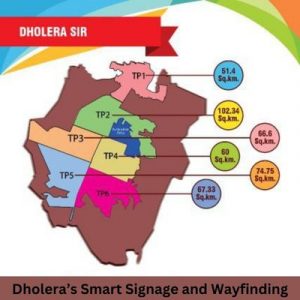

Dholera is envisioned as a smart city that leverages cutting-edge technology to provide efficient and sustainable urban living. The city aims to accommodate over 2 million residents and create numerous job opportunities through its industrial corridors. Key features of Dholera include:

- Smart Infrastructure: Advanced infrastructure with integrated ICT systems for efficient management of resources and services.

- Sustainable Development: Emphasis on green buildings, renewable energy, and eco-friendly transportation systems.

- Economic Hub: Special zones for industrial development, logistics, and commerce to attract global investments.

Given these ambitious goals, the construction industry in Dholera must adopt innovative methods to meet high standards of efficiency, sustainability, and quality. This is where 3D printing technology enters the picture.

Understanding 3D Printing in Construction

3D printing, or additive manufacturing, involves creating three-dimensional objects layer by layer using digital models. In construction, this technology can print components, structures, or even entire buildings using materials such as concrete, plastic, and metal. The process typically involves:

- Design: Creating a digital model of the structure using CAD (Computer-Aided Design) software.

- Printing: Using a 3D printer to deposit material layer by layer according to the digital model.

- Assembly: Assembling printed components into larger structures if necessary.

Key Advantages of 3D Printing in Construction

- Speed: 3D printing can significantly reduce construction time. Entire structures can be printed in a fraction of the time compared to traditional methods.

- Cost-Effectiveness: Reducing material waste and labor costs makes 3D printing an economical option.

- Complex Designs: The technology allows for the creation of complex and intricate designs that are difficult to achieve with conventional construction techniques.

- Sustainability: Using recycled materials and reducing waste contribute to more sustainable construction practices.

- Customization: It allows for easy customization of designs to meet specific requirements without significantly increasing costs.

3D Printing in Dholera: Current Applications

Dholera is leveraging 3D printing technology in several areas of its construction and development projects:

Residential Buildings

3D printing is being used to construct affordable and efficient housing solutions in Dholera. The technology enables the quick erection of residential units with precise designs and minimal waste. This is particularly beneficial in meeting the housing demands of a rapidly growing urban population.

Infrastructure Development

From bridges to public amenities, 3D printing is being applied to various infrastructural projects. The ability to print components off-site and assemble them on-site reduces disruption and accelerates project timelines.

Industrial Structures

Given Dholera’s focus on industrial development, 3D printing is being used to construct factories, warehouses, and other industrial buildings. The technology allows for the quick and efficient setup of facilities, enabling businesses to start operations faster.

Prototyping and Design Testing

3D printing is also used for prototyping and testing new architectural and engineering designs. This allows for the refinement of concepts and identification of potential issues before full-scale construction begins, ensuring better quality and performance of the final structures.

Case Studies: 3D Printing Projects in Dholera

Affordable Housing Project

One of the flagship projects in Dholera involves the construction of affordable housing using 3D printing. This initiative aims to provide quality homes for lower-income groups, addressing the housing shortage in urban areas. The project has demonstrated the capability of 3D printing to produce durable and aesthetically pleasing homes at a lower cost and in less time than traditional methods.

Industrial Complex Development

Another significant application of 3D printing in Dholera is the development of industrial complexes. A notable project includes the construction of a state-of-the-art warehouse using 3D printing technology. This project showcased how 3D printing can reduce construction time and costs while maintaining high standards of quality and safety.

Public Infrastructure

Dholera has also seen the use of 3D printing in public infrastructure projects such as pedestrian bridges and public restrooms. These projects highlight the versatility of 3D printing in creating both functional and innovative public spaces.

Benefits of 3D Printing for Dholera

Economic Growth

The adoption of 3D printing in Dholera’s construction sector is expected to spur economic growth by:

- Attracting Investments: The use of advanced construction technologies can attract domestic and international investors interested in innovative and efficient urban development.

- Creating Jobs: While 3D printing reduces the need for manual labor in construction, it creates new job opportunities in areas such as design, operation, and maintenance of 3D printing equipment.

- Boosting Local Industries: The demand for materials and components used in 3D printing can boost local manufacturing and supply chains.

Environmental Sustainability

3D printing supports Dholera’s sustainability goals through:

- Reducing Waste: Precise material usage minimizes waste, making the construction process more environmentally friendly.

- Recycling Materials: The technology allows for the incorporation of recycled materials into construction, reducing the need for new resources.

- Energy Efficiency: 3D-printed buildings can be designed for better energy efficiency, contributing to lower operational energy consumption.

Enhanced Quality and Safety

The precision and control offered by 3D printing result in higher quality and safer buildings. The ability to test designs through prototypes ensures that potential issues are addressed before construction, leading to more robust and reliable structures.

Challenges and Limitations

While the benefits of 3D printing in construction are significant, several challenges and limitations need to be addressed:

High Initial Costs

The initial investment in 3D printing technology can be high. This includes the cost of printers, materials, and training for personnel. However, these costs are expected to decrease as the technology becomes more widespread.

Material Limitations

Currently, the range of materials that can be used in 3D printing for construction is limited. Research and development are ongoing to expand the variety of usable materials, which will enhance the versatility of the technology.

Regulatory Hurdles

The construction industry is heavily regulated, and the adoption of new technologies like 3D printing may face regulatory challenges. Standards and guidelines for 3D-printed structures need to be developed to ensure safety and compliance with building codes.

Skilled Workforce

There is a need for a skilled workforce proficient in 3D printing technology. Training and education programs are essential to develop the necessary expertise in this emerging field.

The Future of 3D Printing in Dholera and Beyond

The future of 3D printing in Dholera looks promising, with ongoing advancements in technology and increasing adoption across various sectors. The continued integration of 3D printing into construction practices can further enhance Dholera’s position as a leading smart city. Here are some potential future developments:

Integration with Smart City Technologies

3D printing can be integrated with other smart city technologies such as IoT (Internet of Things) and AI (Artificial Intelligence) to create more efficient and responsive urban environments. For instance, IoT sensors embedded in 3D-printed structures can provide real-time data on building performance, enabling proactive maintenance and energy management.

Expanded Use of Sustainable Materials

Research into new sustainable materials for 3D printing is likely to yield options that are even more eco-friendly. This could include the use of bioplastics, composite materials, and other innovative substances that reduce the environmental impact of construction.

Customized Urban Solutions

As 3D printing technology evolves, it will enable more customized urban solutions tailored to specific local needs. This could include everything from personalized housing designs to unique public infrastructure that reflects the cultural and social context of the community.

Collaboration and Innovation

Collaboration between government, academia, and the private sector will drive innovation in 3D printing technology. Public-private partnerships can facilitate the development and implementation of cutting-edge solutions, making Dholera a model for other cities to follow.

Conclusion

3D printing is playing a pivotal role in the construction of Dholera, helping to realize its vision of becoming a leading smart city. The technology offers numerous benefits, including faster construction times, cost savings, and environmental sustainability. While there are challenges to overcome, the potential of 3D printing to revolutionize urban development is undeniable.

As Dholera continues to grow and evolve, the integration of 3D printing into its construction practices will serve as a benchmark for other cities aiming to harness the power of technology for sustainable and efficient urban development. The lessons learned and innovations developed in Dholera will undoubtedly influence the future of construction globally, paving the way for smarter, greener, and more resilient cities.